SCOUT/COMMTEST 200 Series – Advanced Vibration Data Collection & Analysis

SCOUT200 represents the new evolution in portable instruments. It de-couples data acquisition and display, freeing you to use the industrial handheld of your choice, meeting all your needs for screen size, portability, connectivity, flexibility while maintaining industrial strength and options for extreme hazardous area ratings.

Features

On-route & Off-route

for all measurement types: waveforms, spectra, orbits, accel/veloc/displ/demod, process/keypad entry

Analysis at Machine

Bump test, Time Sync Averaging, Order tracking/Sync sampling, Coast-down/Run-up (Interval Capture).

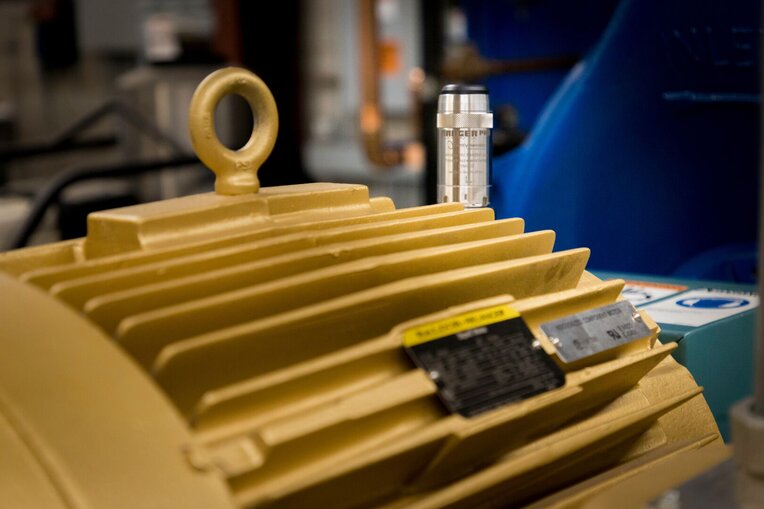

Rugged

Drop tests (1.2m), waterproof (IP65+), long battery life (10+ hrs), light (≤ 1.2kg)

Fast data collection

with automatic settling algorithm, optimized sequencing, and 6Pack superquick measurements.

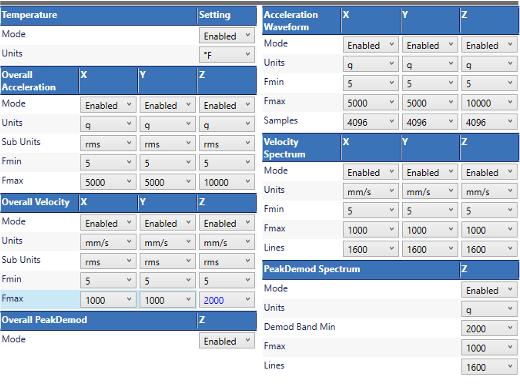

Multi-Channel

Our portable hardware monitoring devices supports multi-channel vibration data collection, analysis, and balancing. Between 1 and 4 channels simultaneous data acquisition, plus tach/keyphasor speed input.

Hazardous Area Certified

SCOUT models certified for ATEX Zone 2/Zone 1 hazardous rating. Neck strap with integrated Sensor Keeper restrains the device while walking or climbing to reach other machines

Offers Channel Options

Available in 2 channel (SCOUT220-IS) or 4 channel (SCOUT240-IS) configurations

Connects with Bluetooth

The data collector uses Bluetooth to communicate with the industrial handheld smartphone or tablet that are rated for hazarous environments

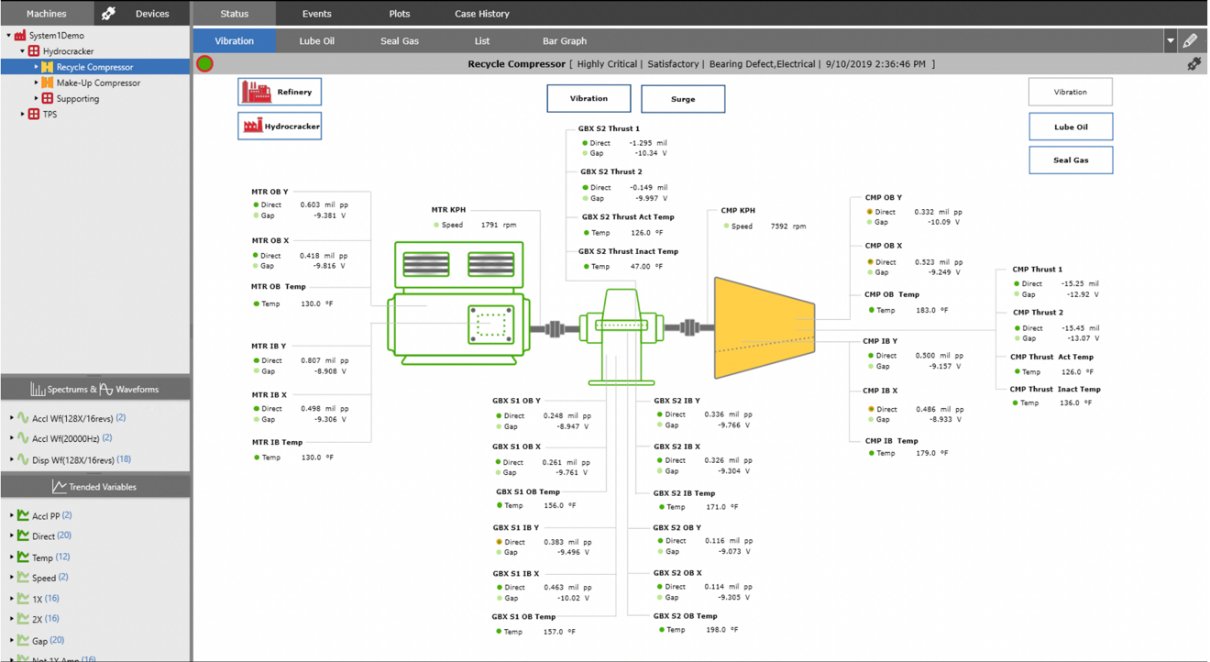

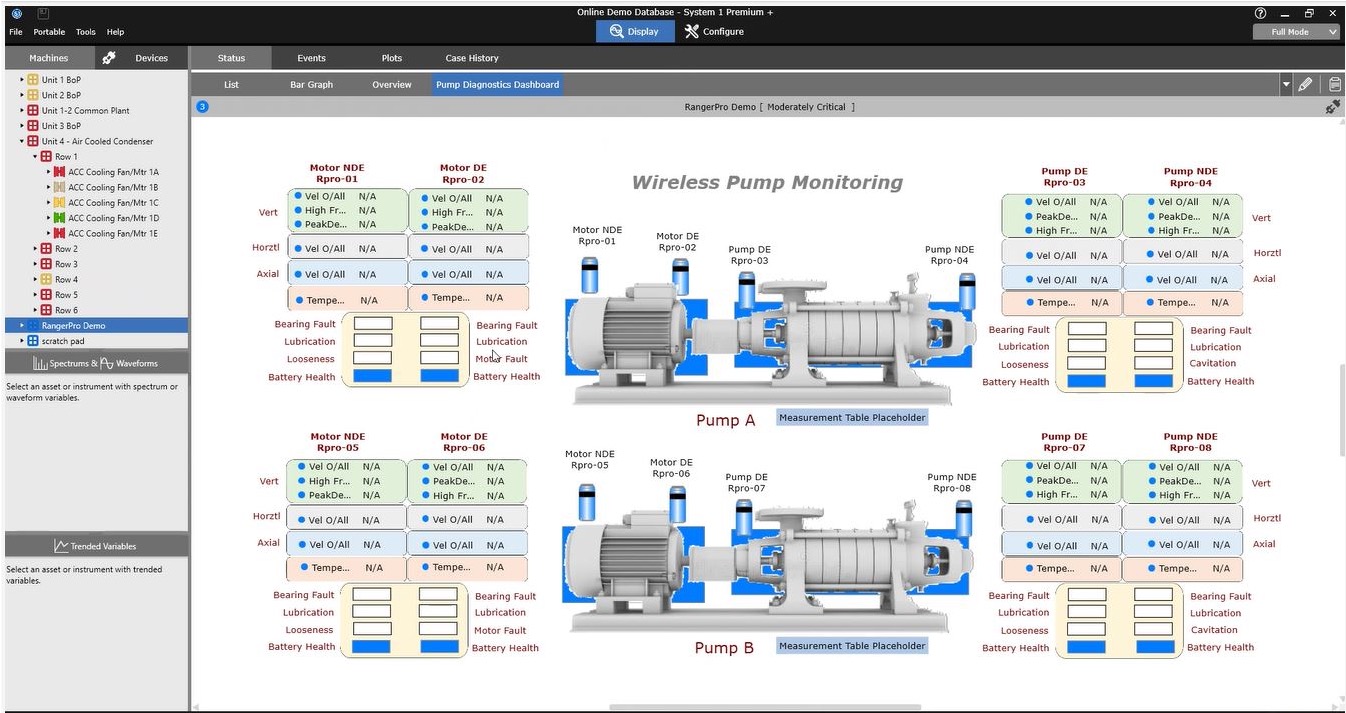

System 1 Software

With Bently Nevada, you have one software program for all your assets and hardware solutions- from online protection and condition monitoring, to online, scanning, wireless and portable condition monitoring solutions.

Tiếng Việt

Tiếng Việt