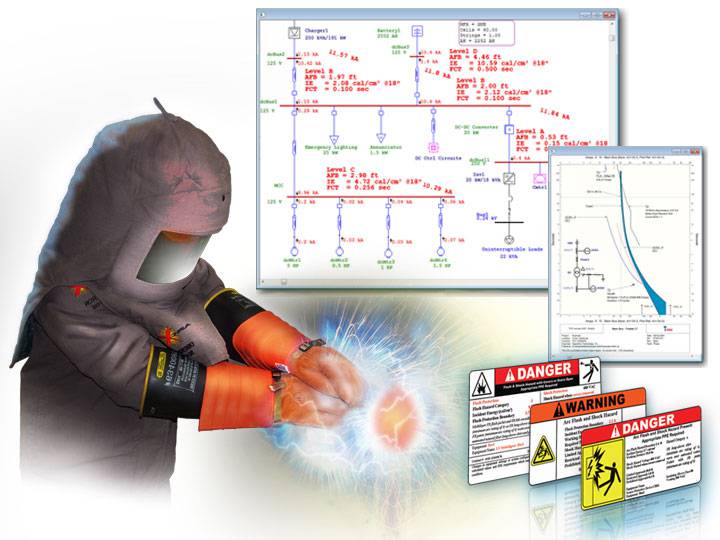

Arc Flash is one of the most serious hazards in electrical systems. During a Short Circuit incident, extremely high fault current can trigger an arc explosion with temperatures reaching up to 35,000°F (≈19,400°C), causing severe burns, permanent injury, or even fatality to operators. Arc Flash Assessment is a critical step in risk assessment, electrical safety guideline design, and ensuring occupational safety.

Benefits of Conducting an Arc Flash Analysis

-

Protecting personnel

Minimizes risk of burns, injuries, or fatalities caused by Arc Flash Incidents -

Regulatory compliance

Meets NFPA 70E, 70B, OSHA, and international safety requirements -

Damage mitigation

Limits equipment damage and reduces downtime during fault events

-

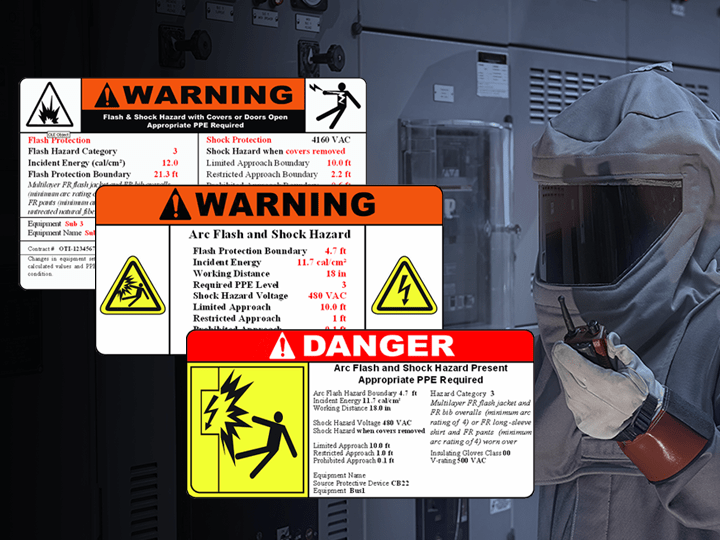

Enhanced awarenessProvides clear hazard warnings, defines Arc Flash Boundaries and PPE

-

System optimization

Reduces Arc Flash Energy levels through design improvements and operational tweaks

Benefits of Arc Flash Assessments

- Determine Arc Flash Energy at each location

Identify energy levels (cal/cm² or J/cm²) throughout the system to evaluate hazard severity and implement appropriate safety measures for personnel. - Calculate the Arc Flash Boundary

Identifies danger zones around electrical equipment to establish warning signage and restricted access areas. - Select Personal Protective Equipment (PPE)

Recommends appropriate PPE levels for each work zone and hazard category.

-

Minimize Arc Flash Energy

Advises optimal methods for each location to reduce Arc Flash Energy through design and operational improvements. -

Ensure compliance with international safety standards

Generates warning labels and detailed reports in line with NFPA 70E, NFPA 70B,IEEE 1584, and OSHA electrical safety requirements.

Outcomes of Arc Flash Study

- Hazard Identification: Calculates arc flash energy and safe working distance.

- PPE Requirements: Specifies suitable protective gear for safe operations.

- Equipment Labeling: Applies warning labels and PPE info on electrical panels.

- Protection System Optimization: Adjusts relays/breakers to minimize incident risk.

- Regulatory Compliance: Ensures adherence to standards like NFPA 70E, NEC, OSHA, IEEE.

- Consulting & Training: Provide expert advice on the most suitable and effective methods, along with comprehensive staff training on hazard awareness and the proper use of PPE.

Tiếng Việt

Tiếng Việt