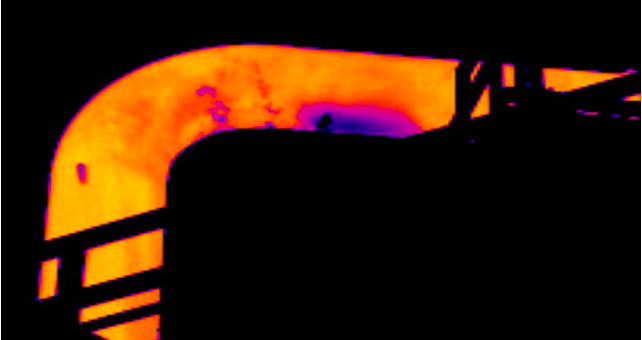

Do we need to perform infrared thermal scanning on electrical equipment?

All electrical equipment will give off some amount of heat during their operation. Normally, this is manageable and does not cause any problems. For electrical distribution systems, the key failure mechanisms are faulty connections, undersized equipment, and wear and tear on protective devices. In all these scenarios before a minor problem manifests itself into downtime and catastrophic failure, hot spots are produced which can be identified in advance and corrective actions can be taken.

Benefits

- Maintain the integrity of your facility’s electrical system

- Reduces electrical fire hazards

- Provide uninterrupted power to tenants/clients/employees

- Detect faulty connections/overloaded circuits

- Provide a snap shot in time of the condition of your mechanical systems, motors, bearings, etc.

- Save costs

Applications

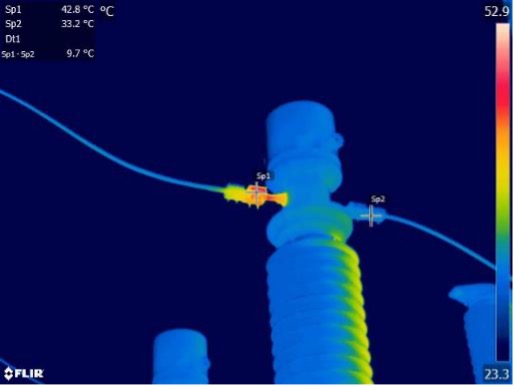

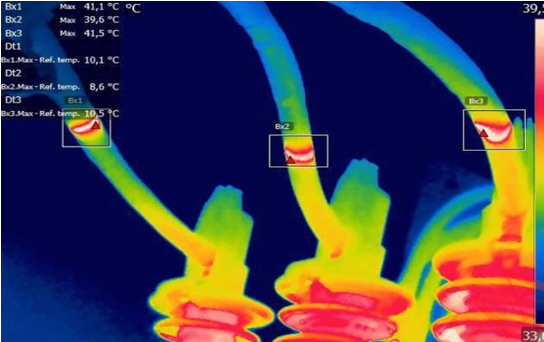

Loose connection inspection

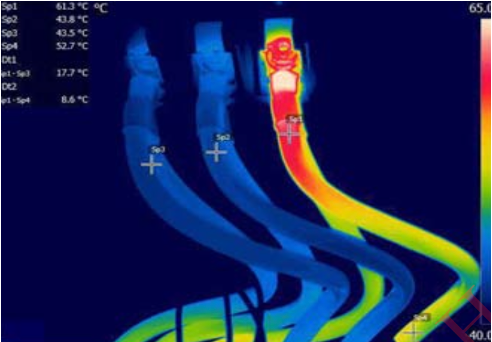

Wrong cable termination installation

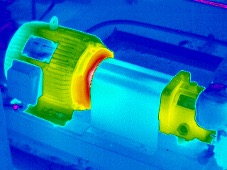

Motor inspection

Tiếng Việt

Tiếng Việt