What is Partial Discharge?

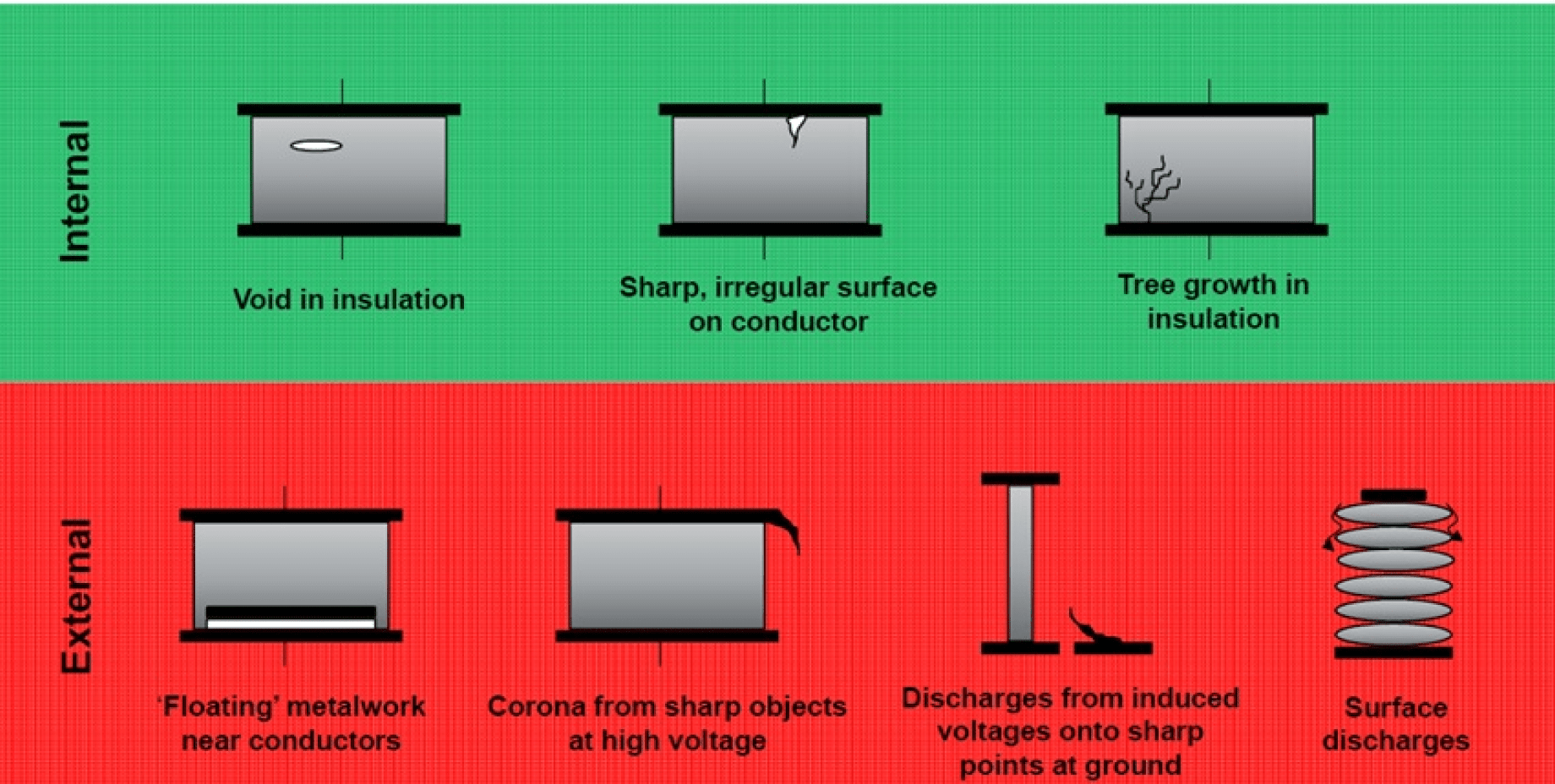

A Partial Discharge (PD) is an electrical discharge or spark that bridges a small portion of the insulation between two conducting electrodes. Partial Discharge activity can occur at any point in the insulation system, where the electric field strength exceeds the breakdown strength of that portion of the insulating material. These discharges erode insulation and eventually result in insulation failure.

According to the National Fire Protection Association (NFPA 70B), the leading cause of electrical failures is insulation breakdown. The National Electrical Code (NEC) states that these partial discharges are the first indication of insulation deterioration. IEEE Gold Book, Table 36, indicates that cables, switchgear, and transformers suffer the greatest losses from insulation failure.

Our team conducts an online periodic testing using a Portable PD tester with noninvasive sensors. Our multi-purpose PD handheld device is able to conduct the initial pre-screen to identify the critical equipment for testing. Typically, only 5 to 10% of medium and high voltage assets will have significant levels of PD activity. This prescreening will provide the required data to develop an overall test plan to ensure focus on the right assets, minimizing unnecessary spending.

Once the assets are prioritized, our engineers conduct the periodic PD measurements using non-invasive, calibrated PD sensors including Ultra High Frequency (UHF) sensors, High Frequency Current Transformer (HFCT) sensors, Transient Earth Voltage (TEV) sensors, or Airborne Acoustic sensors. These sensors are inductively, capacitively, or acoustically coupled to the equipment to provide online PD testing while the equipment remains energized. By synchronizing PD signal with electric cycle and utilizing advanced analysis software, the test engineers are able to observe phase-related patterns of discharges. It is crucial to determine the type of discharges and their severity levels.

The diagnostic phase typically involves a multi-channel test unit, with synchronous data acquisition on 4 or more channels. This type of technology allows more detailed testing to be undertaken where Online Partial Discharge (OLPD) data is collected from all three phases at once. This enables discharge type, phase-to-phase or phase-to-earth, to be ascertained. If OLPD activity is detected, then the diagnostic testing is extended to locate the source of the PD site(s) within the circuit under test.

Sometimes, you may need to conduct continuous monitoring over a short period. A portable PD Monitor can be used to perform continuous monitoring from one hour up to several months. Through continuous monitoring, our team will trend your assets over a longer period of time to provide a more accurate assessment and recommendation. This solution provides most of the advantages of the permanent OLPD continuous monitoring when a lower budget is available whilst allowing for multiple substations to be monitored sequentially.

Our continuous OLPD monitoring system is able to provide an early warning against HV insulation failure through developing insulation faults, including critical assets that are nearing the end of their life. The continuous OLPD monitoring systems detect operational and environmental variations in PD activity and provide the best warning against HV insulation failure. This early warning needs to provide sufficient time to schedule a planned, preventative maintenance intervention at minimum cost and maximum convenience for the operator, whilst avoiding what can be a very costly, unplanned outage.

Why our service stands out from others?

High quality standards

We use calibrated testing equipment certified engineers (International Level 1 & 2 Certified OLPD Engineer). We never compromise with our quality in services. Our engineers have profound knowledge and real-life experiences in partial discharge detection and analysis. We have built a library of numerous case studies for reference and systemic approach to different customers.

Applying advanced technology

We are technology centered rather than promoting particular brand name or manufacturer, so that we utilize cross-platform and combination of different Technology, UE Systems, HVPD, PMDT and Emerson. We combine different methods and sensors for cross check and guarantee the result.

Professional team

We are the only one team that is able to do the diagnosis as well as the repair at the same time. Our solid foundation of many years performing preventive maintenance and corrective maintenance give us insights to propose effective solution for the problem with confidence. If MV cable has problem, our qualified MV cable jointer can fix it or insulation of bushing is deteriorated, our maintenance team can strengthen it by applying insulation epoxy. As promised, we find your problems, we fix them and we re-check for a guaranteed resolution.

Tiếng Việt

Tiếng Việt