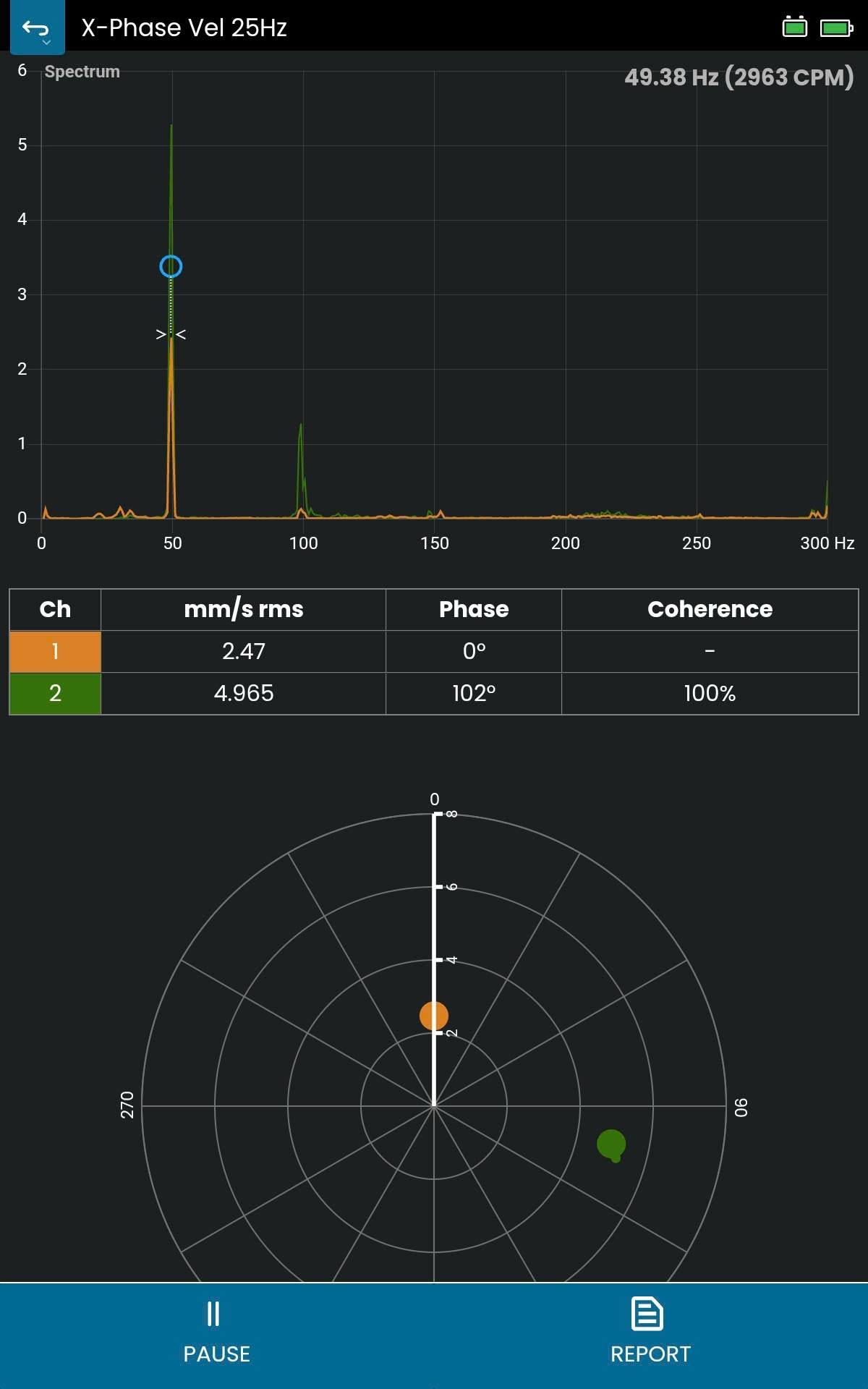

In industrial plants (cement, steel, F&B,…), a lot of rotating machineries are used such as: motor, fan, pump, compressor, gearbox,… and are applying a periodic/preventive maintenance program or unscheduled repair (run to fail) maintenance. However, these maintenance programs are not cost-effective, increases spare parts, and does not optimize machinery life. The CBM (Condition Based Maintenance) program will overcome this disadvantage, increase reliability and prevent serious damage. Among the CBM diagnostic technologies, vibration analysis is currently the most.

Tiếng Việt

Tiếng Việt