Wireless temperature and partial discharge monitoring sensor

Continuous monitoring, easy installation and operation, optimal investment costs

All medium voltage cabinets include basic equipment: Medium voltage bars (running along the entire row of cabinets), medium voltage circuit breakers, current transformers, medium voltage underground cables, disconnectors, and grounding switches. All of these devices need to be monitored for temperature, however, monitoring the temperature of components in closed cabinets is difficult due to the narrow operating space, and the difficulty of using thermal imaging cameras, which also leads to errors during measurement. In addition, periodic, intermittent monitoring leads to not proactively monitoring incidents where heat increase is one of the primary factors.

Equipping an online, continuous temperature monitoring solution with immediate alerts to operations managers is extremely necessary. In addition, the system requires equipment components that are easy to install, require no maintenance, and are highly reliable and accurate. VTI Corp offers a solution using wireless, battery-free sensors that are completely suitable for continuous temperature monitoring of components in the cabinet.

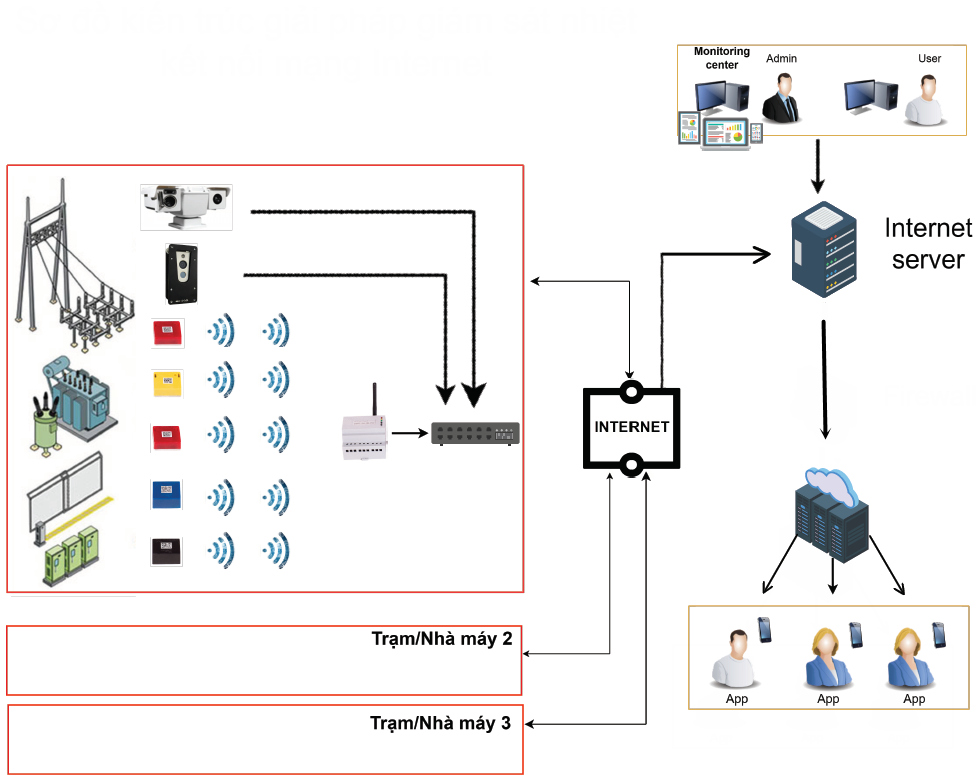

System structure

System Structure

Sensor

Wireless temperature sensor, without battery/or with battery, can be easily installed at points that need to measure temperature

Gateway

Collects data from thermal sensors over large distances; Unlimited number of sensors

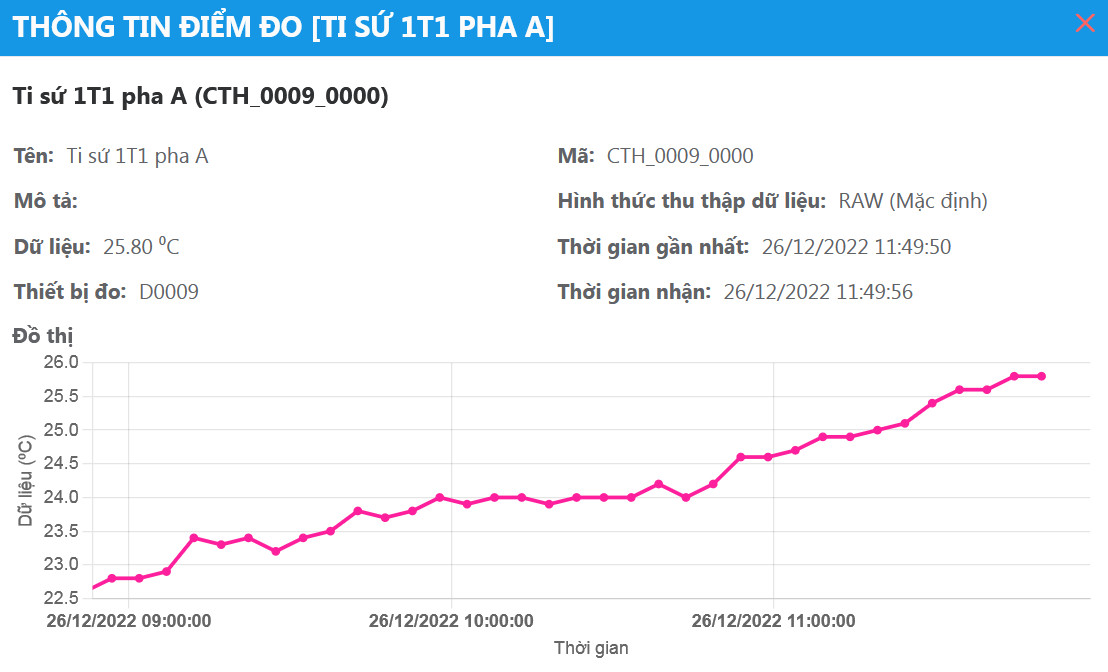

Central software

Continuous monitoring and instant warnings of temperature measuring points; Analyze data and analyze trends to evaluate equipment status; Able to integrate with component monitoring systems in the substation; Connect to SCADA to retrieve data or serve data input for the CBM system.

Mobile application

Application on mobile devices for iOS and Android operating systems helps operations managers monitor and receive warnings anytime, anywhere.

Tiếng Việt

Tiếng Việt